Add to Cart

What is the Carbide Woodturning Tool?

All of our inserts and cutters are manufactured to our specifications using high grade carbide, they are finely ground to a razor cutting edge with toughness and durability for long-lasting, smooth cutting in the most dense hardwoods.

What is the Feature of Carbide Woodturning Inserts?

1. Strong and sharp cutting edge,easy to replace your jointers and planers

2. A wide range of products for cutting,turning and threading;

3. Wear resistance with high toughness: resulting in increased tool life, reduction in number of tool changes, reduced grinding and lower production costs.

4. Resistant to corrosion: protection against chemical influences such as resin

5. Resistant to oxidation: protection against thermal influences

6. Resistant to abrasion: protection against mechanical wear

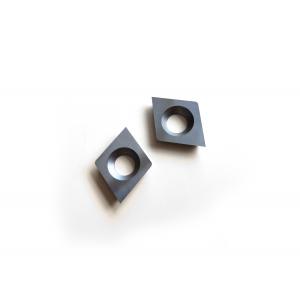

What Does your Woodturning Inserts Look Like?

What is the Specification of Woodturning Inserts?

What is the Advantage of Woodturning Inserts?

-- We only use the finest virgin tungsten carbide powder.

-- Tungsten carbide wood working inserts differ in size and grade, in this way offering optimum characteristics for the different fields of application.

-- Continunally highly important quality assurance by carrying out stringent endurance testing during the manufacturing process.

-- Factory-direct shipment ensure short delivery time when you need it, 15~25 days.

-- Treat our customer like treat ourself.

Experienced team on your service to help you find a solution that will offer increased productivity and longer life, reducing down time and saving you money.

What is the Application?

Our Carbide Woodturning Inserts will be used for your wood turning job.

How to Use Carbide Woodturning Inserts?

1: Position the tool rest as close to the work as possible so the carbide cutter is at the lathe center line.

2: Place the tool on the tool rest with the tool shaft parallel with the floor.

3: While securely holding the tool to keep the flat bottom in constant contact with the tool rest slowly plunge the carbide cutter into the work.

What Should We Pay attention to?

1: When you are on the working, please remember to protect your eyes from flying debris!

2: Please don’t let children touch it.

3: Prevent moisture.

PACKAGE:

Standard export carton packing

DELIVERY TIME:

2-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity